Minimum Submergence-this may be a term you’ve heard in the past and often associated with submersible pumps. But what does it really mean?

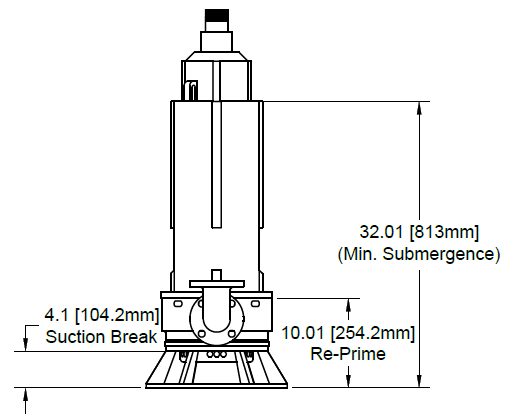

Submersible pumps are a unique piece of equipment in which the electric motor is designed to operate in the sump fluid. Unlike common fan cooled motors, submersible motors are totally enclosed, non-ventilated (TENV) and require the operating heat to dissipate to the surrounding sump fluid. The minimum submergence dimension is the lowest fluid level recommended to keep the motor adequately covered for proper cooling.

What if the sump needs to be drained lower than this minimum submergence dimension?

The standard R-Series submersible pumps carry a 15 minute in air rating. This means the motors can operate without being cooled via fluid submergence for 15 minutes. Extended in air operation can lead to overheating and result in motor damage. R-Series pump motors are equipped with 2 normally closed thermostats. These thermostat contacts will open if the motor temperature rises too high and prevent damage associated with overheating.

What if the sump fluid level is consistently below the minimum submergence level?

The R-Series submersible pump can be configured to safely run continuously in air via an engineered Continuous In Air (CIA) rated motor. This motor is oversized and constructed of higher temperature tolerant materials to dissipate heat to the surrounding air.

Do you have a sump with unique challenges?

- Low sump fluid level

- High temperature

- Abrasive

- Corrosive

- High altitude

Industries Served

- Steel/metals production

- Mining

- Power generation

- Oil and gas

- Any severe abrasive or corrosive service sump

The engineered R-Series submersible pump may be the solution to your specific application.