A submersible pump’s mechanical seal is the most critical component in keeping the pump in operation. The seal has a challenging job-keep a submerged electrical motor protected from the outside elements. Take a closer look at one of the R-Series pump mechanical seal configurations and the steps RIG has taken to keep your pump running longer in the most demanding applications.

Previously, the details of the Internal Double Slurry Seal were discussed. Now it’s time to learn about the second seal option.

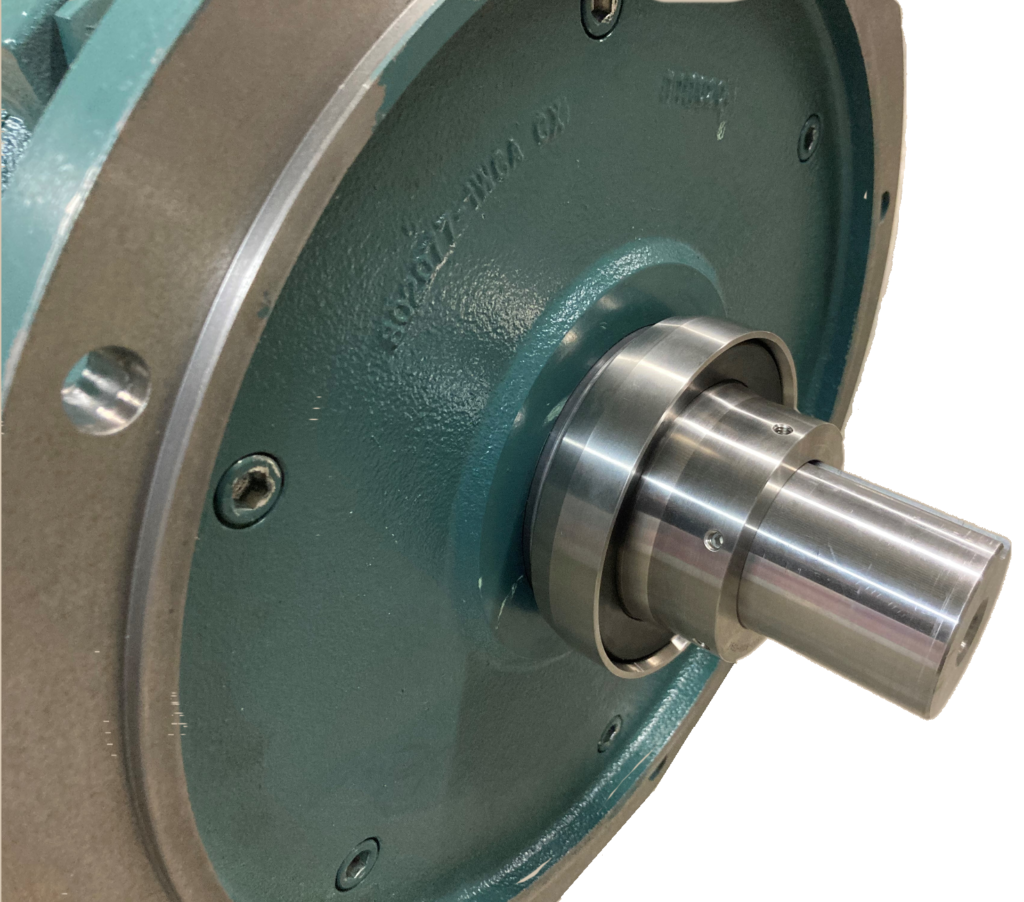

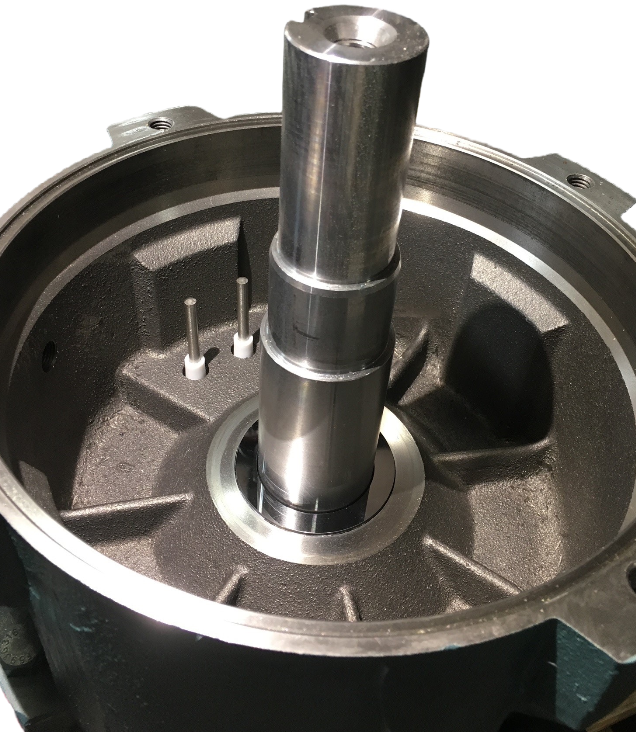

The Tandem Slurry Seal is a mechanical seal arrangement of two independent seal systems. There is an internal John Crane Type 21 (inboard) upper seal and separate external John Crane Type 5840 (outboard) seal.

- Motor Shaft

- Type 5840 Lower Rotating Assembly (Silicon Carbide Face)

- Type 5840 Lower Stationary Assembly (Silicon Carbide Face)

- Anti-Rotation Pin

- Oil Chamber

- Type 21 Upper Seal Spring

- Type 21 Upper Rotating Face (Carbon)

- Type 21 Upper Stationary Face (Ceramic)

- Moisture Detection Probes

- Motor Mounting Flange to Pump

The Tandem Slurry Seal is RIG’s heavy duty seal offering and recommended for the most demanding applications. The Type 5840 outboard seal features duplex stainless steel construction, silicon carbide faces, and TFE Propylene elastomers. Seal components are enclosed and protected from the harsh service. In addition, the stationary assembly is secured via an anti-rotation pin. The 5840 is also available in super duplex 2507 and Alloy C726 construction for severe corrosive service.

Moisture probes are located in the oil chamber and when used in conjunction with a relay box will notify the user of seal failure.

Advantages

- 2 independent seals

- Enclosed seal components

- Higher pressure & radial limits

- Several material choices

- Can be used on UL motor

- Repairable

Limitations

- Not dry run capable

- Higher initial cost

Stay tuned for more Deep Dive technical articles in the future.