The R-Series submersible slurry pump is available in several different alloys to best fit a specific application’s challenges. Previously, the abrasion resistant high chrome iron was covered. Today’s alloy focus is stainless steel and its variants.

Stainless steel is an iron alloy with chromium and other elements to increase corrosion resistance over traditional steel. 300 series stainless steels are known for their enhanced corrosion resistance by using nickel while 400 series usually offer increased strength and hardness. 304 is the most common grade of stainless steel. It may be referred to as “18-8” as a nod to its chromium and nickel content respectively. 316 (also known as “marine grade”)stainless adds a small amount of molybdenum to further resist chloride corrosion. Duplex stainless steels (two phase structure) like 2205 (22% chromium, 5% nickel) and CD4 often match or exceed the corrosion resistance of the 300 series metals while offering improved strength and hardness. For more severe chloride applications a super duplex stainless steel like 2507 (25% chromium, 7% nickel) could be used.

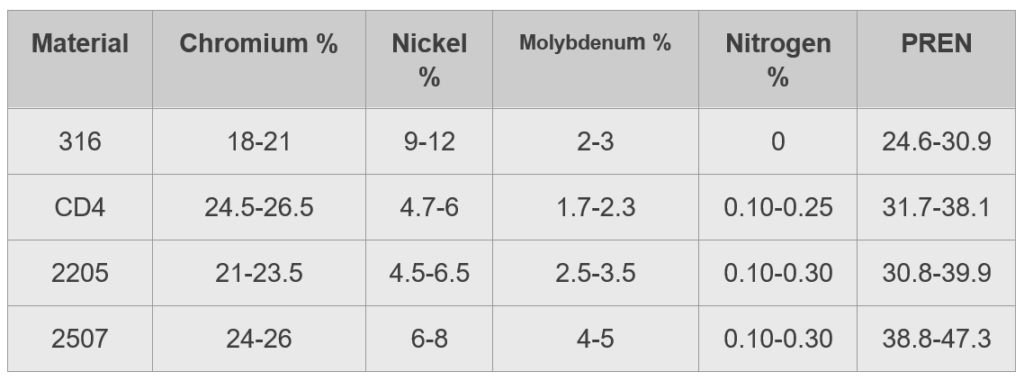

One way to compare the corrosion resistance of these materials is through the Pitting Resistance Equivalent Number (PREN). The formula is below and takes into account the chromium, molybdenum, tungsten (when applicable), and nitrogen content of metals. The higher the content of these elements, the more pitting resistance at a tradeoff of often increased cost.

PREN = %Cr + 3.3(%Mo + 0.5 x %W) + (16 x %N)

The PREN is a useful tool for comparing metals but should not be the sole factor in a material selection. A metal’s resistance to stress corrosion cracking and crevice corrosion cracking should also be taken into account.

The R-Series submersible pumps are available in the following stainless steel alloys:

Industries often requiring corrosive resistant sump pumps:

- Chemical

- Paper

- Mining

- Power generation

- Wastewater

- Oil and gas